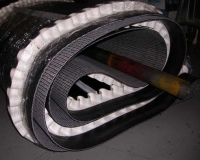

The company’s standard conveyor belting, for example, employs low stretch EP fabric abrasion resistant rubber covers and is BS490 and DIN22 102 compliant. The belts are impervious to humidity and wet, and offer high tear resistance. For the inclined conveying (in excess of 18 deg) of bulk materials, the company can supply a complete range of chevron belts.

CONVEYOR PULLEYS RUBBERFIX PTY LTD can also supply a range of special purpose conveyor belts such as canvas back grip top, canvas back smooth top, and cleated belts. To complement these there is an extensive selection of belt fasteners, clips and tooling on offer as well as an on-site belt fastening service, should it be required. CONVEYOR PULLEYS – RUBBERFIX PTY LTD experienced belt operatives are even on hand 24 hours a day to provide a complete on-site vulcanising service for all belts up to 2.1m wide.

– Stock includes standard conveyor belting.

– EP Carcass widths up to 2100mm.

– Chevron belting – cleat height 15mm/25mm/32mm.

– Heat and oil resistant belting.

– Grip top and plain top packaging belting.

– Sawtooth and herringbone incline belts.

– Agricultural and food belts.

Types:

– According to its functions, the covering rubber can be divided into types of common, heat-resistance, cold-resistance, alkaline-resistance.oil-resistance, static-resistance, etc.

– Heavy duty – hard rock mining, severe abuse

– Hard rock mining and heavy quarrying

– Medium quarrying sand/gravel

– Light duty grain & sand plants

– Wood chip and slider bed applications.

– Resists pine sap.

– Medium fire resistance for sugar grain, coal handling

– Oil and heat resistance. Lumps to 230oC, fines to 120oC

– Maximum heat resistance for fine materials to 225oC. Lumps to 420oC